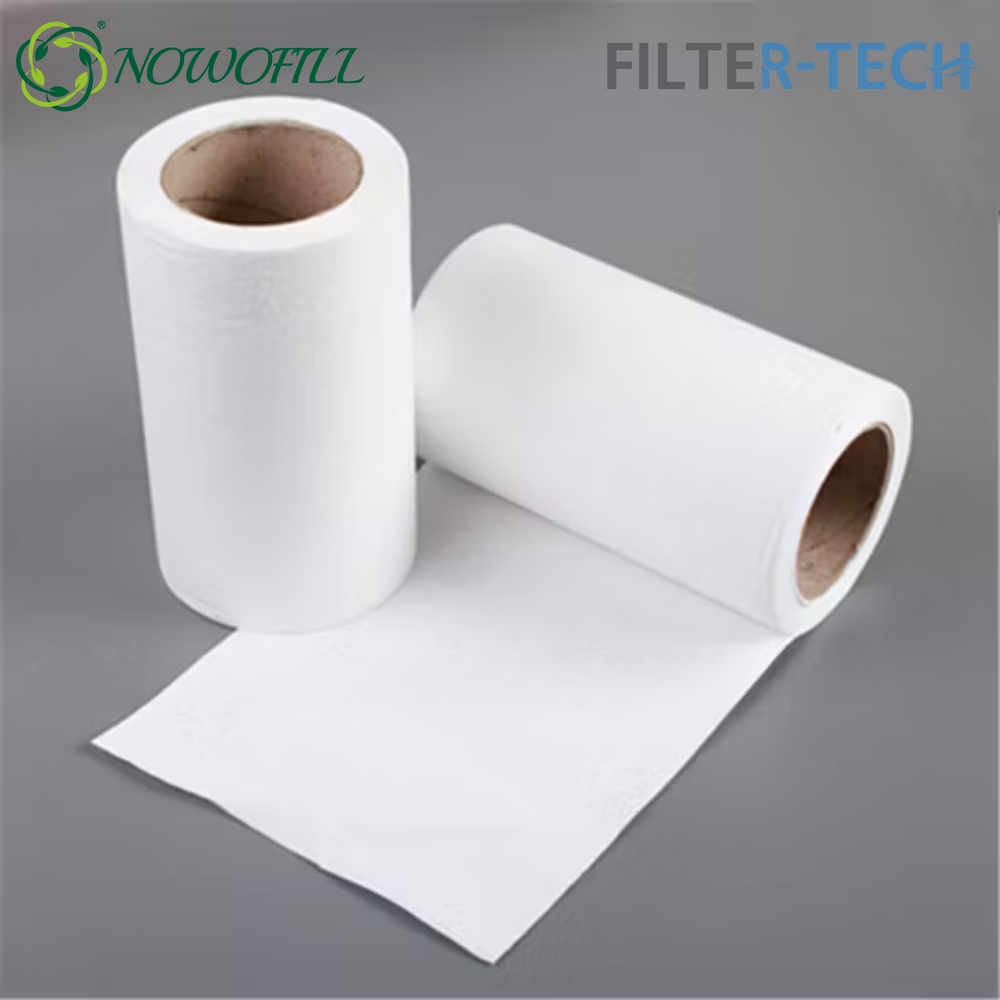

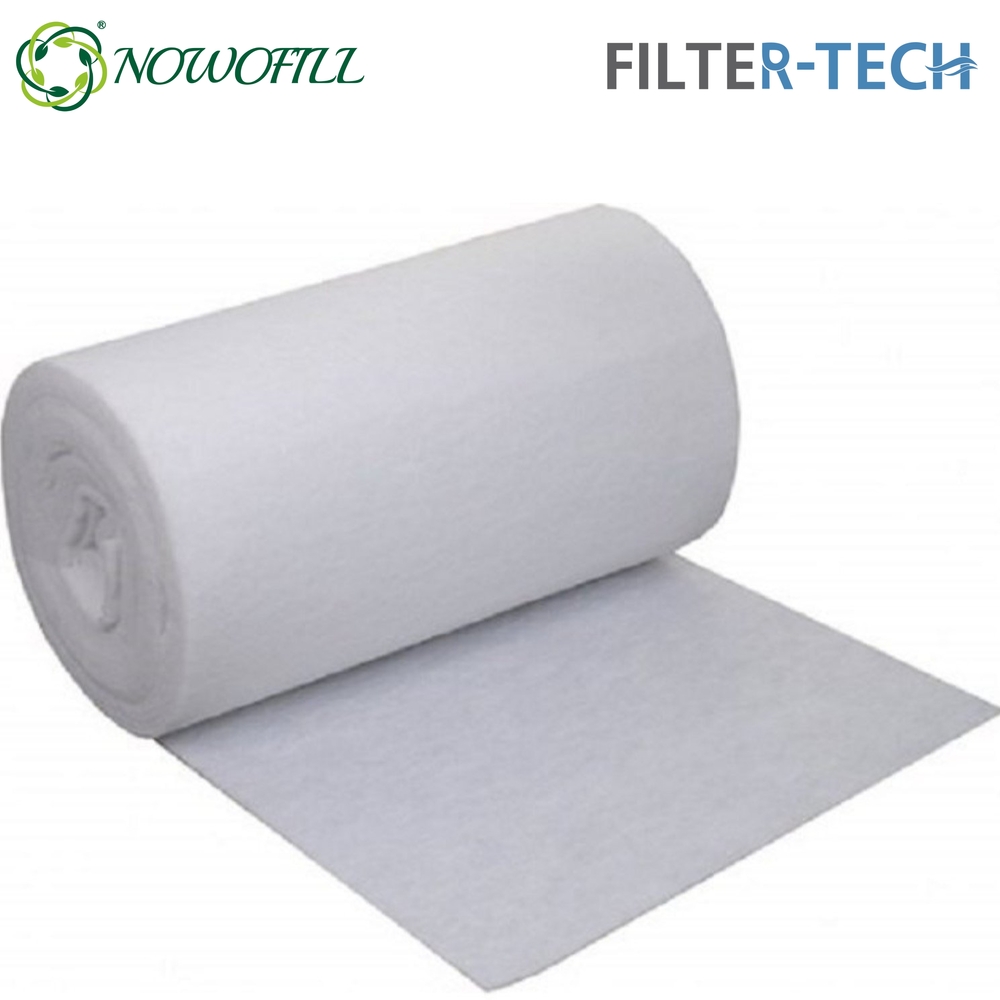

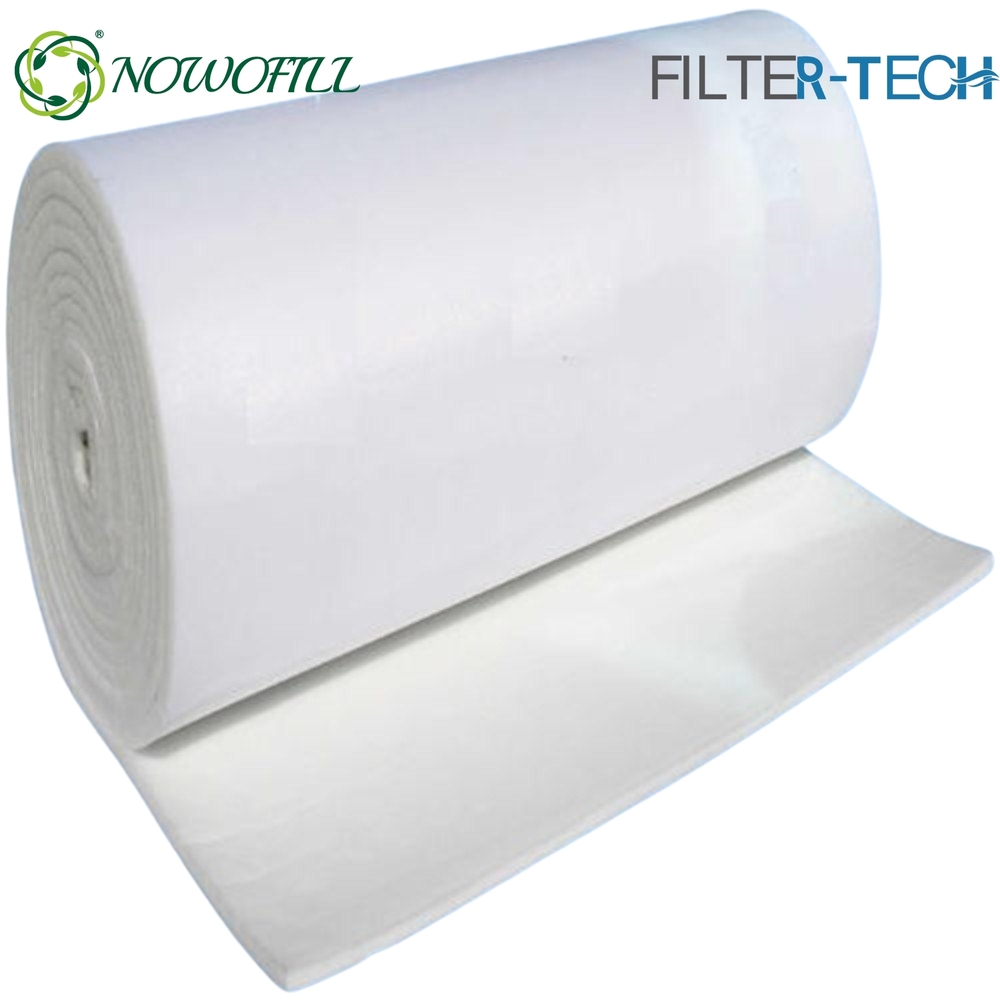

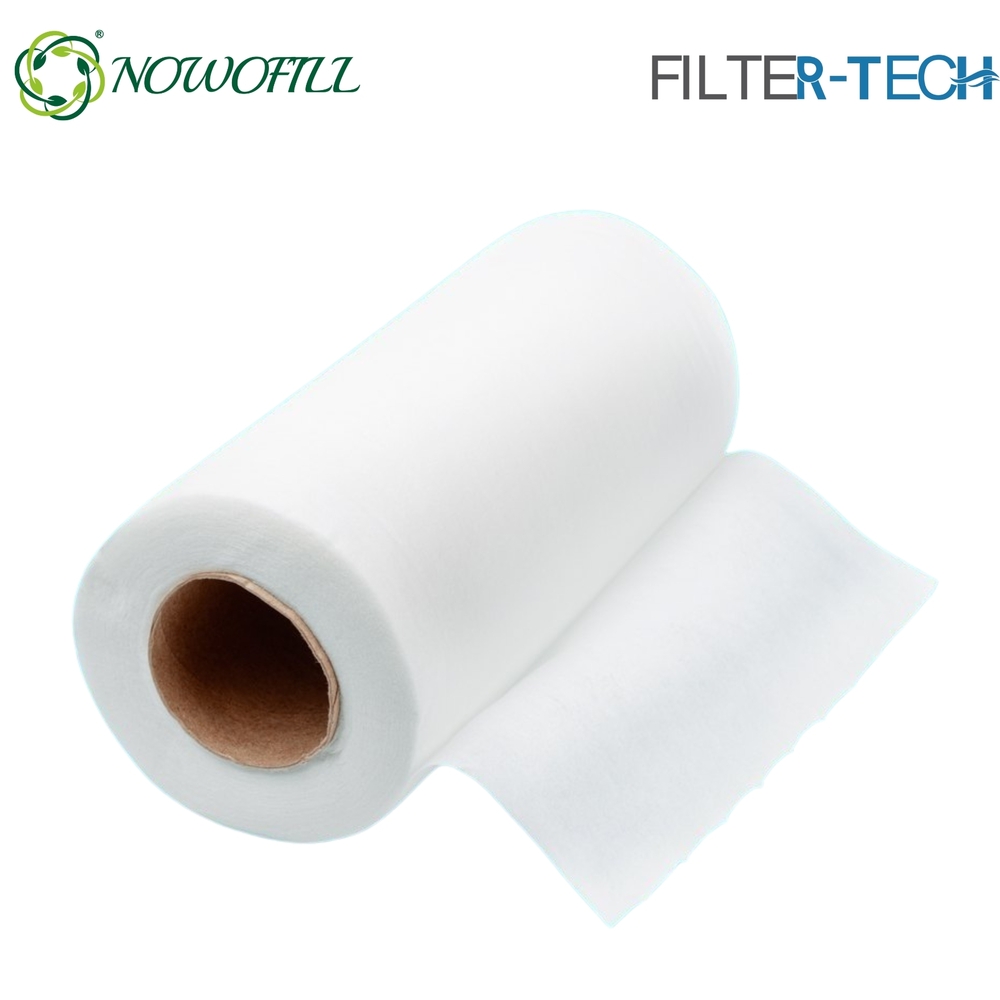

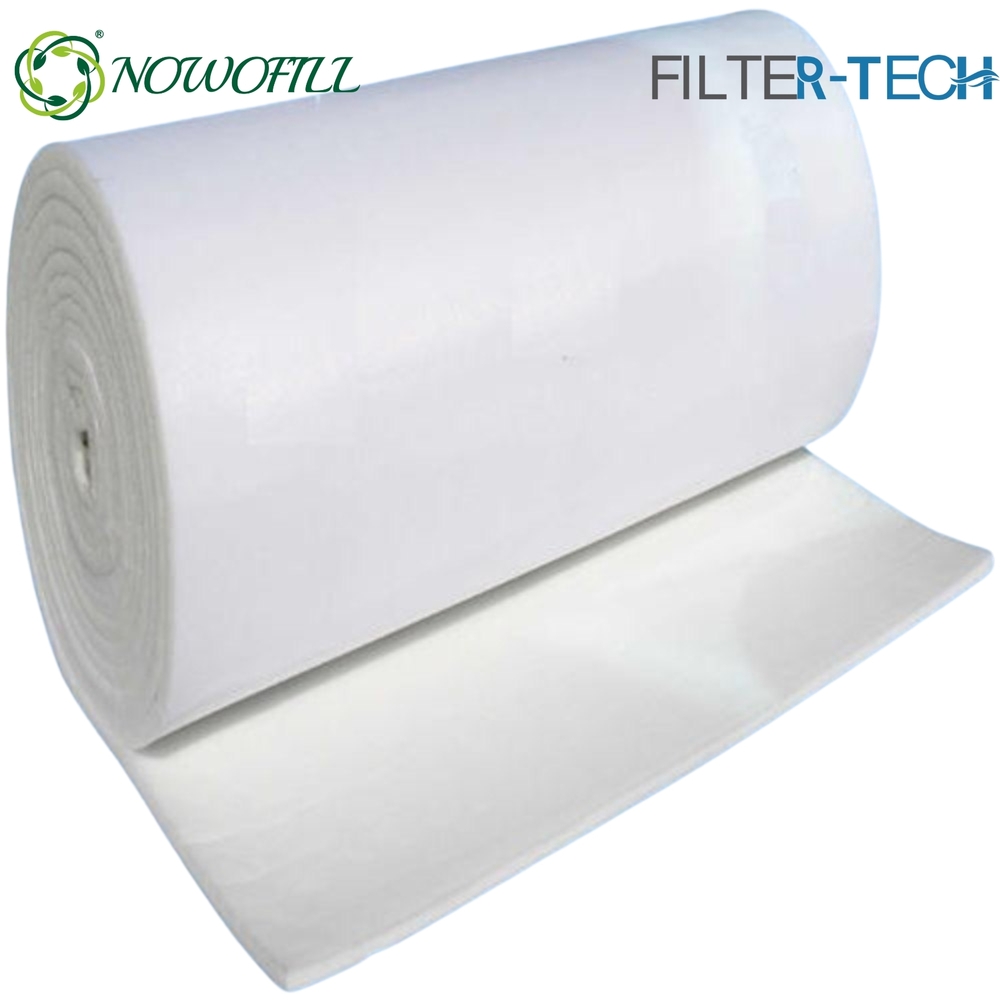

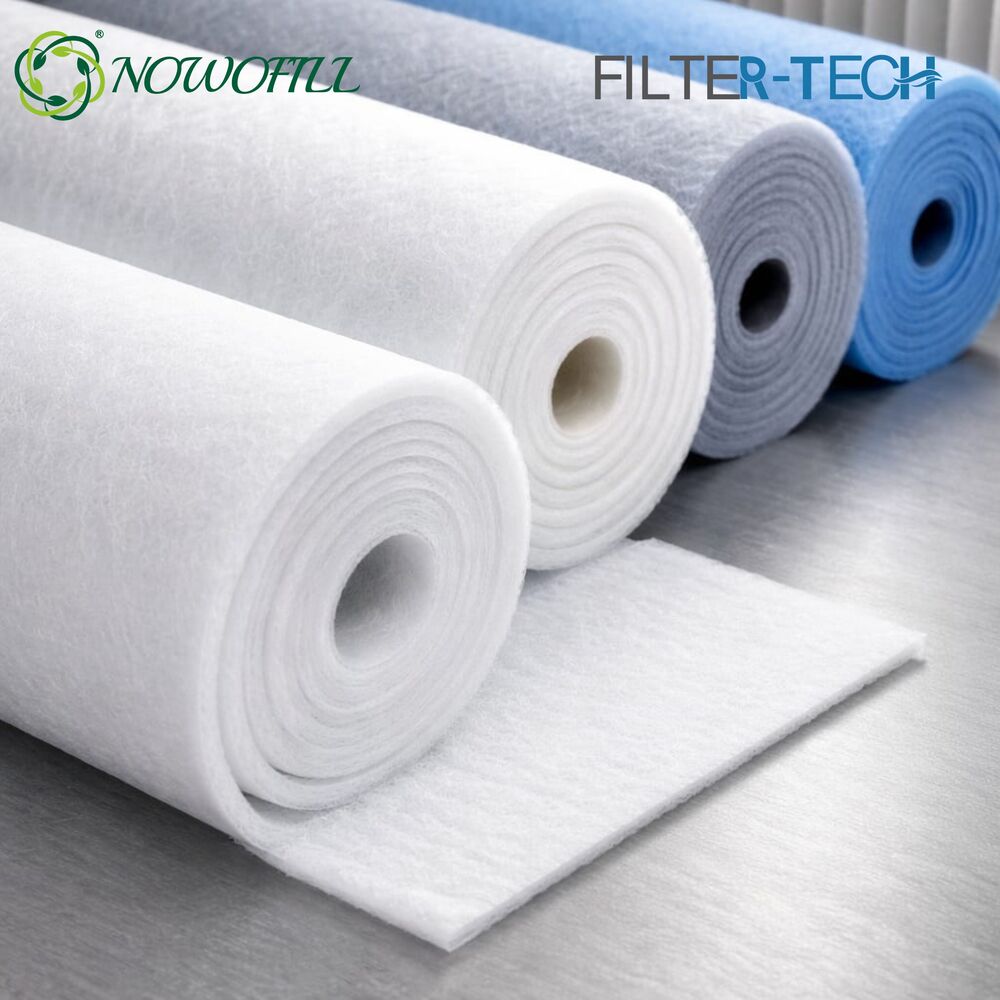

Polyester Filter Wadding.

Price 58 INR/ Meter

Polyester Filter Wadding. Specification

- Material

- Polyester

- Fabric Type

- Filter Media

- GSM

- 200

- Application

- Chemical Industry Filtration Applications

- Color

- White

- Pattern

- Plain

- Width

- 40-45 Inch (in)

- Weight

- 200 GSM (gm/2)

- Usage & Applications

- Filling material

- Print Type

- Plain

- Polyester Texture

- Non Woven

- Style

- Plaid

- Recommended Season

- Summers, Autumn

- Length x Width

- 1000 Meter (m)

Polyester Filter Wadding. Trade Information

- Minimum Order Quantity

- 1000 Meter

- FOB Port

- LDPE Jute

- Payment Terms

- Paypal, Cash in Advance (CID)

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Polyester Filter Wadding.

Nowofill Polyester Filter Wadding is a high-quality nonwoven material made from premium polyester fibers, designed for efficient air and liquid filtration. It offers excellent dust-holding capacity, chemical resistance, and dimensional stability, ensuring consistent performance in filtration systems. Lightweight yet durable, this wadding is ideal for HVAC systems, industrial dust collectors, automotive filters, and liquid filtration applications. With superior airflow and long service life, Polyester Filter Wadding provides reliable, energy-efficient filtration for industrial, commercial, and residential environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Filter media Category

Air Filter.

Price 85 INR / Meter

Minimum Order Quantity : 1000

Usage & Applications : Filling material

Print Type : Plain

Weight : 200 GSM (gm/2)

Style : Plaid

Nonwoven Filter Cloth.

Price 64 INR / Meter

Minimum Order Quantity : 5000

Usage & Applications : Filling material

Print Type : Plain

Weight : 150 GSM (gm/2)

Style : Plaid

G1 Filter media.

Price 48 INR / Meter

Minimum Order Quantity : 1000

Usage & Applications : Filling material

Print Type : Plain

Weight : 200 GSM (gm/2)

Style : Plaid

Filter Cloth media.

Price 90 INR / Meter

Minimum Order Quantity : 1000

Usage & Applications : Filling material

Print Type : Plain

Weight : 200 GSM (gm/2)

Style : Plaid

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS