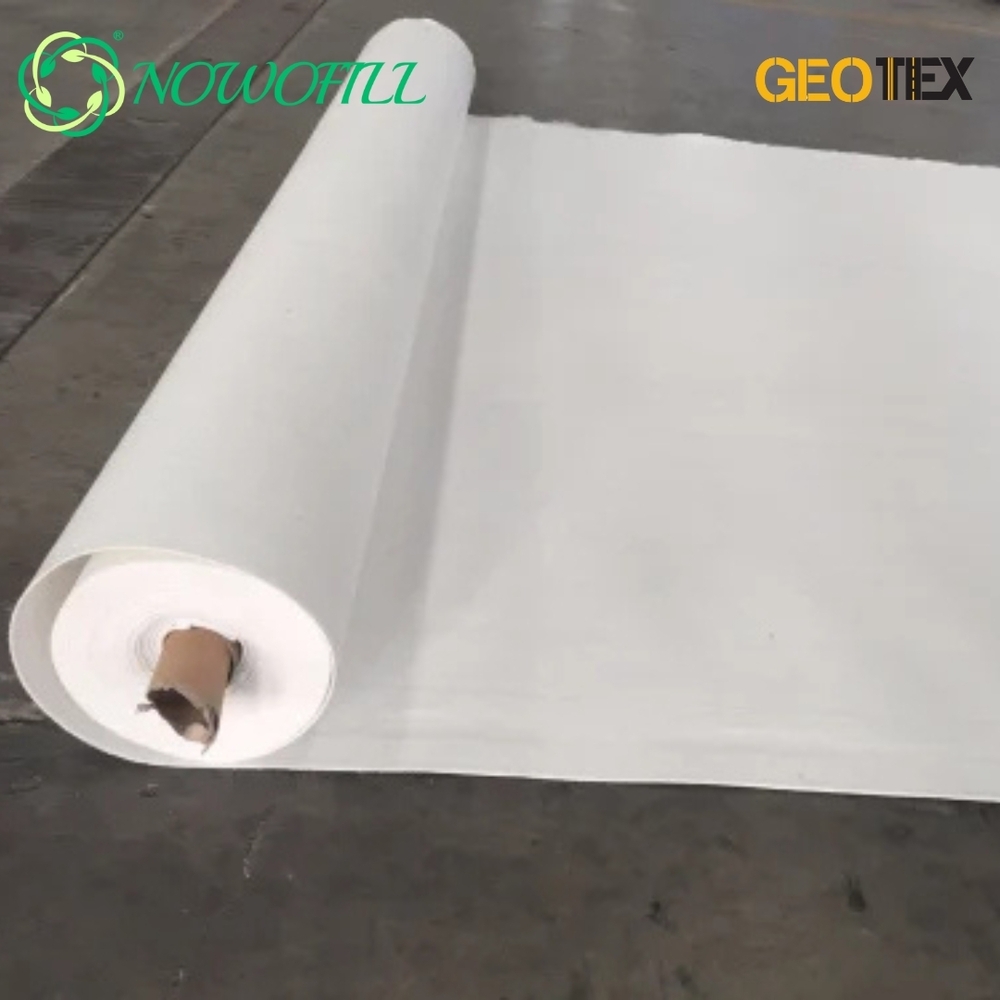

Nonwoven Geotextiles

Nonwoven Geotextiles Specification

- Material

- Polypropylene / Polyester (as per requirement)

- Georgette Texture

- Nonwoven

- Georgette Style

- Needle Punched or Heat Bonded

- Characteristics

- High strength, Durability, Excellent permeability, Chemical resistance, UV stabilized, Tear resistant

- Application

- Separation, Filtration, Drainage, Protection, Reinforcement in civil engineering work like road construction, railways, embankments, retaining structures, and landfills.

- Length x Width

- 4 m x 50 m (custom sizes available)

- Color Detail

- Standard White (also available in Black or Custom upon request)

- Disposable

- Yes

- Color

- White, Black, Grey

- Thickness

- 0.8 mm to 5 mm (varies with GSM)

Nonwoven Geotextiles Trade Information

- Minimum Order Quantity

- 100 Meters

- FOB Port

- Jaipur

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10000 Meters Per Week

- Delivery Time

- 2-3 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia, North America

- Main Domestic Market

- All India

About Nonwoven Geotextiles

Advanced Features and Diverse Applications of Nonwoven Geotextiles

These machine-manufactured geotextiles boast high strength, exceptional durability, and advanced chemical resistance, thanks to a needle-punched or thermal bonded process. Lavishly engineered for superior permeability and tear resistance, they suit a variety of applications beyond the ordinaryranging from protection and reinforcement in embankments and retaining structures to high-performance filtration in drainage and landfills. Special features include customizable GSM and thickness, making them adaptable for multiple uses in civil engineering and industrial sectors.

Market Reach, Export Opportunities, and Shipping Details of Nonwoven Geotextiles

Positioned with competitive charge and high market value, our nonwoven geotextiles are widely supplied across the main domestic market and exported globally. Shipped goods depart from major FOB ports, ensuring prompt delivery to key markets in Asia, Africa, Europe, and the Middle East. Our products enjoy robust demand among importers, exporters, contractors, and service providers, underpinning foundational infrastructure improvements worldwide.

FAQs of Nonwoven Geotextiles:

Q: How are nonwoven geotextiles typically installed?

A: Nonwoven geotextiles are usually rolled out onto the prepared ground surface and can be cut to fit required dimensions. The process involves laying the fabric flat, ensuring complete coverage, and overlapping seams according to project specifications before backfilling or covering.Q: What benefits do nonwoven geotextiles offer in civil engineering projects?

A: These geotextiles provide high strength, durability, and excellent permeability, making them ideal for separation, filtration, drainage, and reinforcement. Their resistance to chemicals, UV rays, and punctures enhances service life in demanding applications like roads, railways, and landfills.Q: Where can nonwoven geotextiles be used effectively?

A: They are versatile for use in road construction, railway works, embankment stabilization, retaining walls, landfills, and drainage systems, as well as other civil engineering applications requiring separation and reinforcement.Q: What materials are nonwoven geotextiles made from?

A: Our nonwoven geotextiles are produced from high-quality polypropylene or polyester, available as needle punched or heat bonded varieties to suit a range of technical requirements.Q: When should a higher GSM geotextile be selected?

A: Choose a higher GSM geotextile when greater tensile strength, durability, or enhanced puncture resistance is required, particularly in areas expecting high loads or aggressive environmental conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Geotextile Products Category

Geo BagsFabric.

Price 50 INR / Meter

Minimum Order Quantity : 1000

Application : Riverbank and shoreline protection

Material : Polyester

Usage & Applications : Filling material

Color : White

Geotextile Fabric For Roof Gardens

Price 25 INR / Meter

Minimum Order Quantity : 1000

Application : Durable, permeable, lightweight,

Material : Polyester

Usage & Applications : Filling material

Color : Black

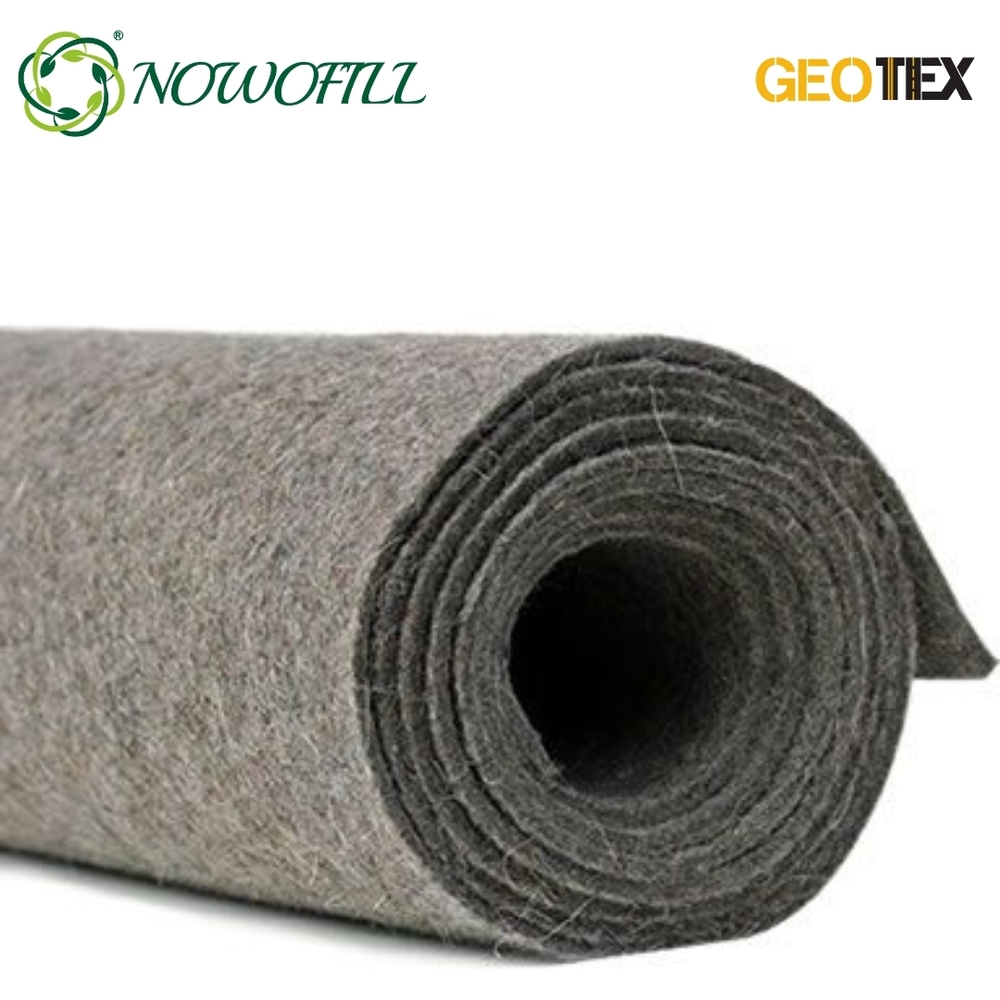

Needle Punched Geotextile Fabric

Price 25 INR / Meter

Minimum Order Quantity : 1000

Application : Retaining walls and gabion support

Material : Polyester

Usage & Applications : Filling material

Color : Grey

PP Non Woven Needle Punch Geotextiles

Price 28 INR / Square Meter

Minimum Order Quantity : 5000 Square Meters

Application : Erosion control and slope protection

Material : Polyester

Usage & Applications : Filling material

Color : Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free