Iron Board Felts.

Price 45 INR/ Meter

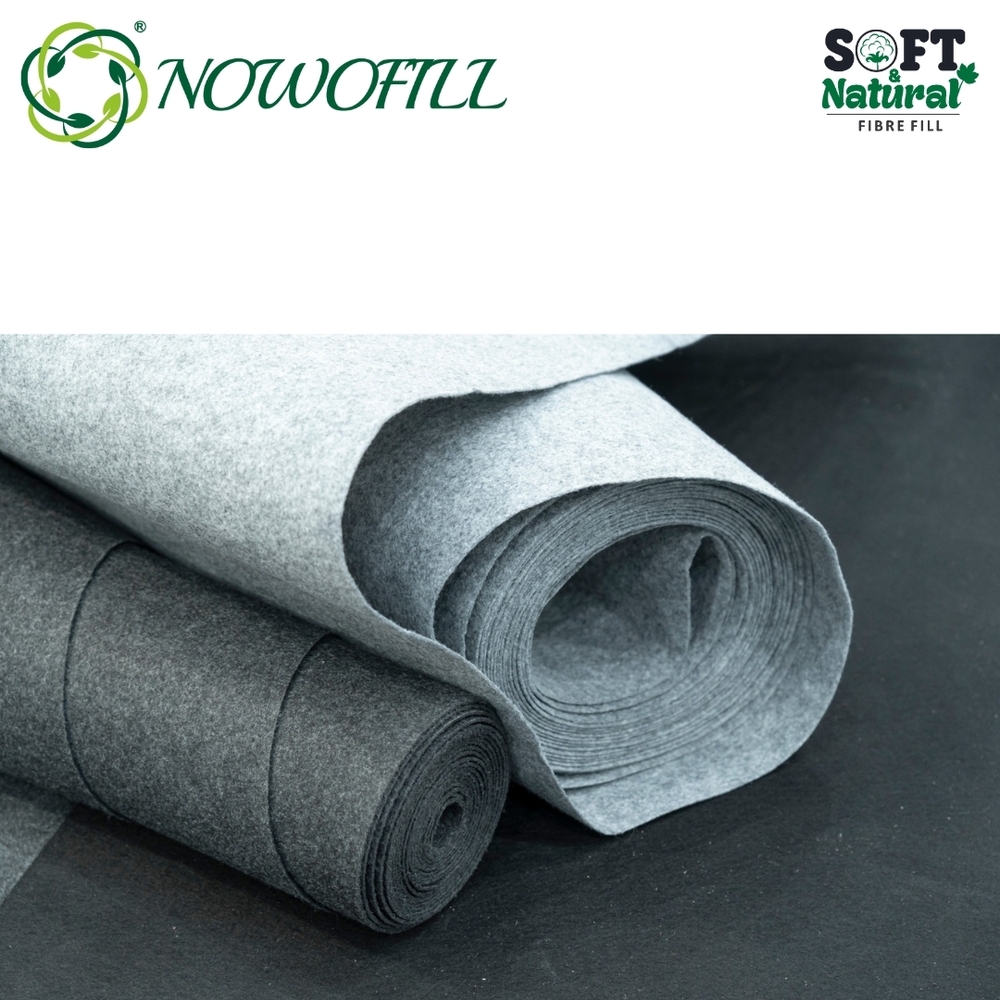

Iron Board Felts. Specification

- Width

- 40-45 Inch (in)

- GSM

- 200

- Application

- Clothing Maintenance and Care Centers

- Material

- Needle

- Usage & Applications

- Filling material

- Fabric Type

- Iron

- Print Type

- Plain

- Length

- 1000 Meter (m)

- Texture

- Plain

Iron Board Felts. Trade Information

- Minimum Order Quantity

- 1000 Meter

- FOB Port

- LDPE Just

- Payment Terms

- Paypal, Cash in Advance (CID)

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

About Iron Board Felts.

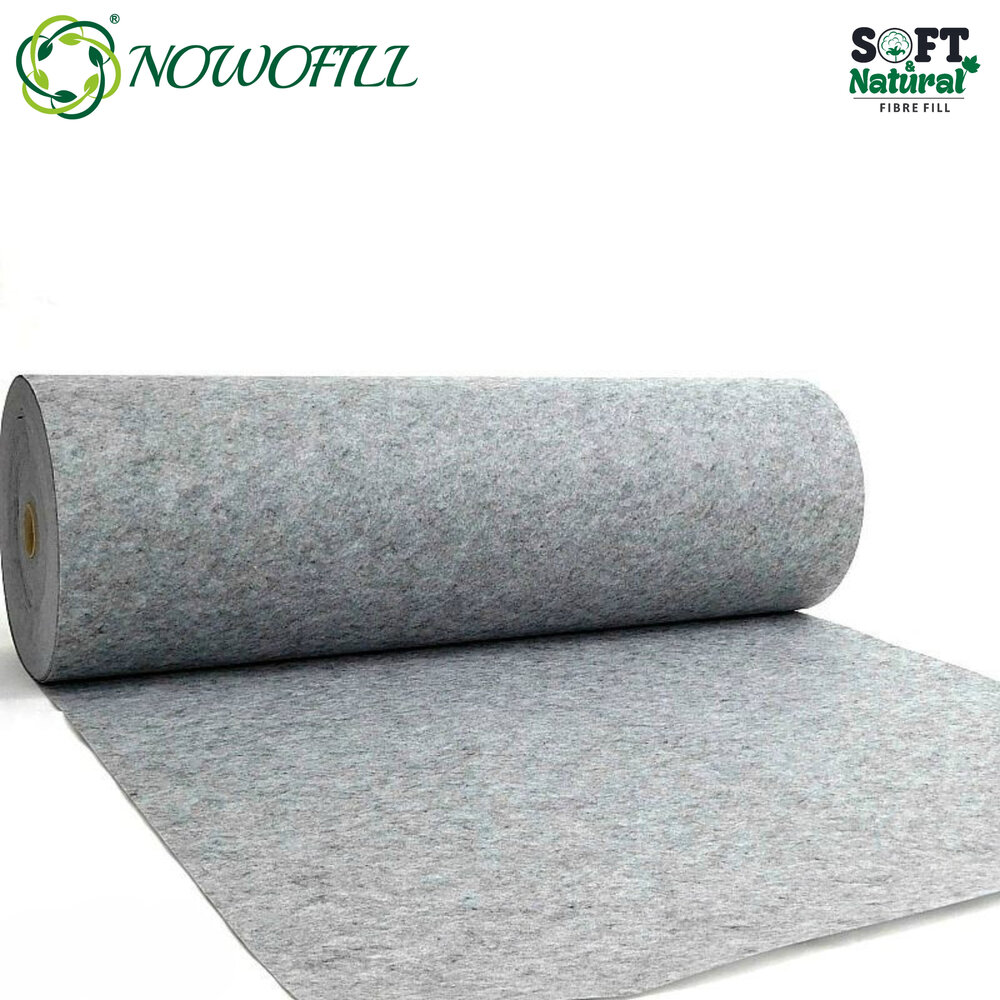

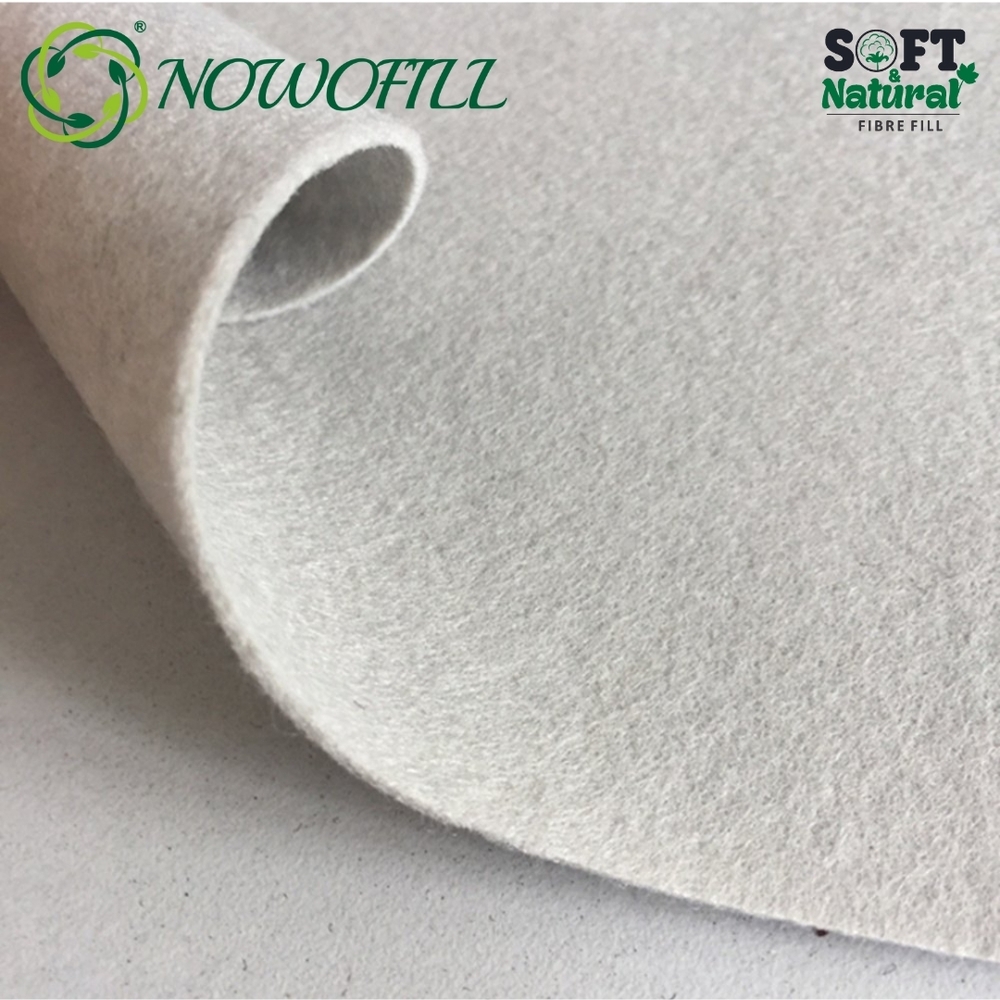

Nowofill Iron Board Felts made from high-quality heat-resistant fibers, designed to provide excellent insulation, cushioning, and durability for ironing boards. Soft yet resilient, they protect surfaces while ensuring smooth and efficient ironing performance. Resistant to high temperatures and deformation, offering long-lasting use. Easy to cut, fit, and replace on various ironing board sizes. Available in different thicknesses, densities, and roll sizes to meet diverse domestic and industrial ironing applications, combining comfort, safety, and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Needle Punch Felt Category

Non-Woven Needle Punch Fabric .

Price 60 INR / Meter

Minimum Order Quantity : 1000

GSM : 200

Print Type : Plain

Application : Furniture padding and upholstery support

Color : Grey

Needle Punch Polyester Felts. .

Price 60 INR / Meter

Minimum Order Quantity : 1000

GSM : 200

Print Type : Plain

Application : Carpet backing and flooring underlay

Color : Grey

Shoe Felts Needle Punch . .

Price 50 INR / Meter

Minimum Order Quantity : 1000

GSM : 200

Print Type : Plain

Application : Footwear padding and cushioning laye

Color : Grey

Non Woven Needle punch Felt .

Price 35 INR / Meter

Minimum Order Quantity : 5000

GSM : 150

Print Type : Plain

Application : Mattress and bedding lining

Color : Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS