Price 48 आईएनआर/ Meter

Specification

- शब्दावली

- सूत की गिनती

- Not applicable (nonwoven).

- घनत्व

- ग्राम प्रति घन सेंटीमीटर (g/cm3)

- सूत का प्रकार

- Staple fiber.

- कपड़े की क्षमता

- Designed for high dust loading and extended service life.

- संकोचन

- Low shrinkage (<1%) under recommended operating conditions.

- पैटर्न

- फ़ैब्रिक टाइप

- Nonwoven needle punch felt.

- फ़ीचर

- वज़न

- 300 - 600 gsm (customizable).

- मटेरियल

- पॉलिएस्टर टेक्सचर

- स्टाइल

- शाइन

- अनुशंसित सीज़न

- सामान्य निर्देश

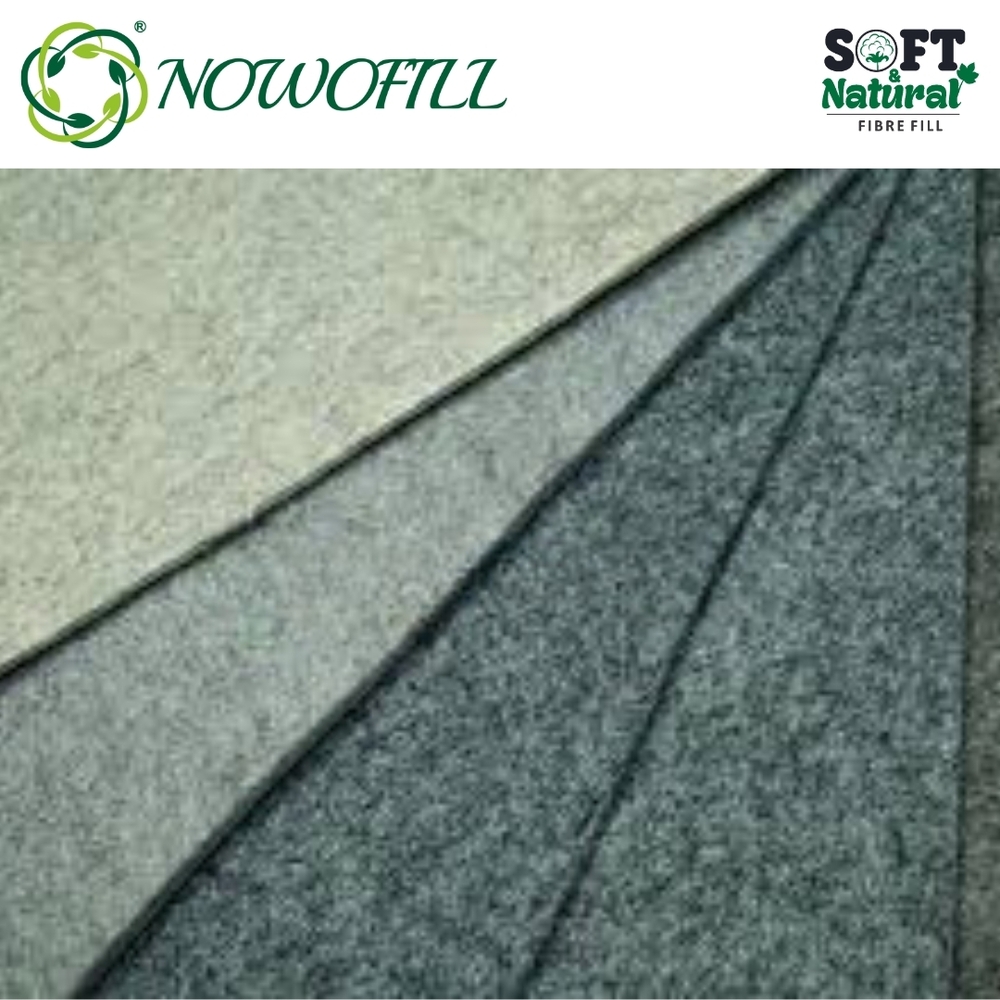

- रंग का विवरण

- White or off-white.

About

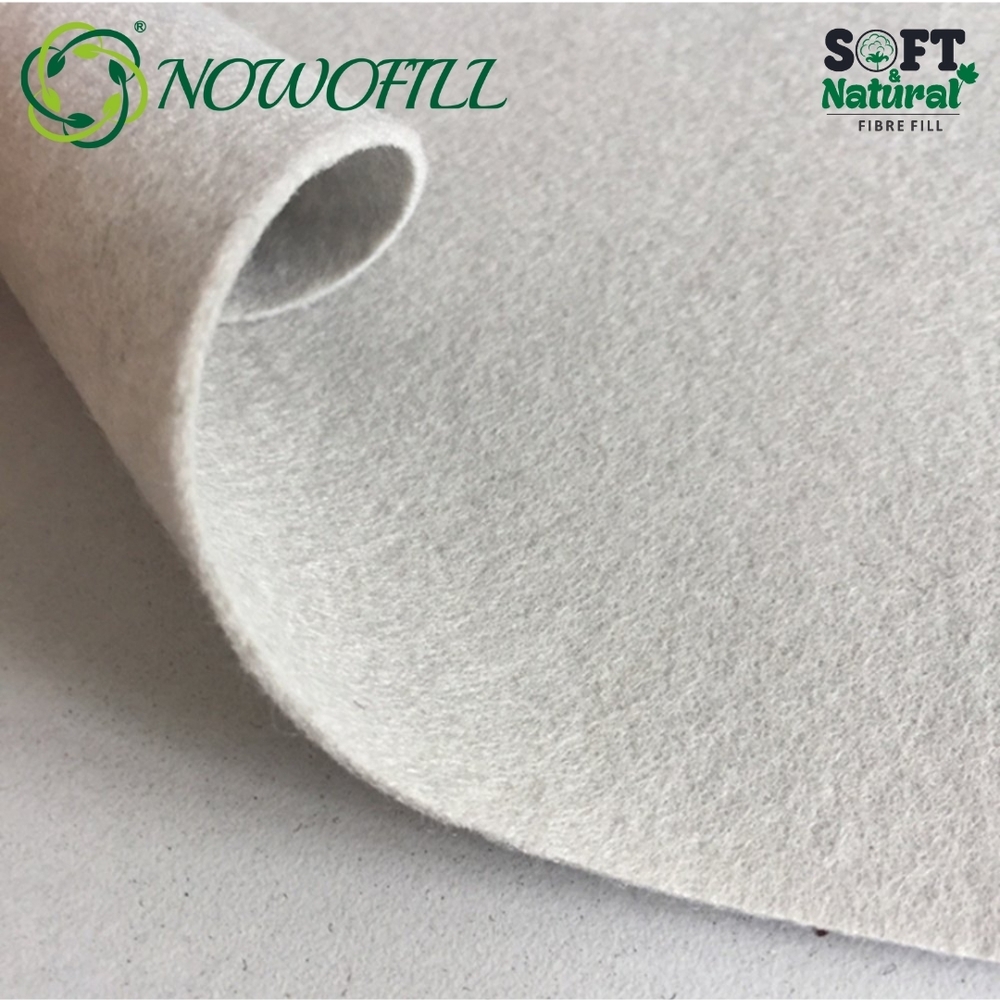

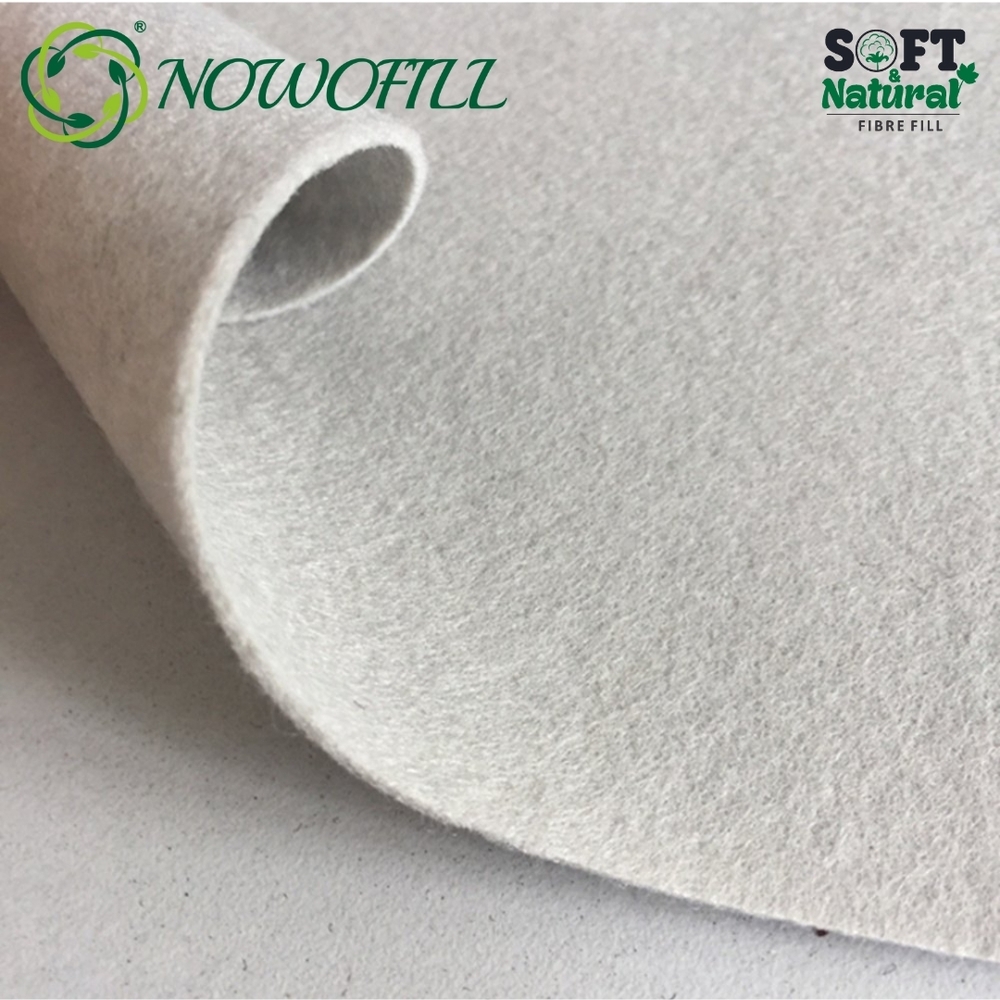

Nowofill Needle Punch Filter Felt is a high-performance nonwoven filtration material engineered using precision needle-punching technology. Made from polyester, polypropylene, or aramid fibers, it offers excellent air permeability, mechanical strength, and chemical resistance. Ideal for industrial dust collection, air purification, and liquid filtration systems, it ensures efficient particle capture and long service life. Widely used in cement, power, pharmaceutical, and chemical industries, Needle Punch Filter Felt delivers reliable, durable, and energy-efficient filtration performance.

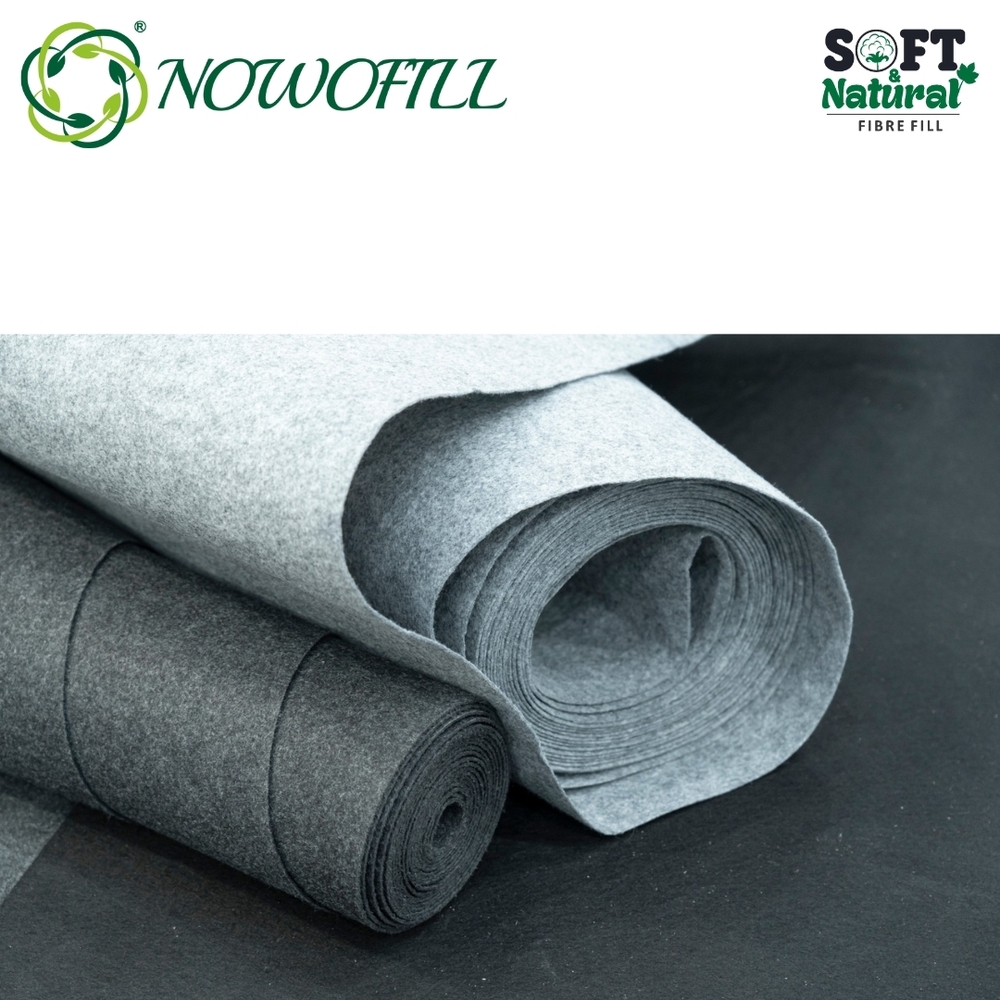

Versatile Filtration for Demanding Applications

Engineered for dust collection, liquid separation, and industrial filtration, Needle Punch Filter Felt suits diverse sectors from chemical processing to cleanrooms. Its customizable thickness, filtration precision, and wide temperature tolerance support various system requirements, delivering consistently high performance for both dry and wet processes. Each roll or sheet is protected during shipment, ensuring the product arrives in pristine condition, ready for use.

Customizable Construction and Durability

With thickness options ranging from 1 to 3 mm, as well as customizable density (300 g/cm) and roll size, this felt can be tailored to specific operational needs. The seamless integration of staple fibers by needle-punching technology provides excellent filtration efficiency and long service life. Optional seam types include ultrasonic, heat welded, or stitched edges, all enhancing product durability in challenging environments.

FAQs of Needle Punch Filter Felt:

Q: How is Needle Punch Filter Felt customized to suit different filtration requirements?

A: Needle Punch Filter Felt is available with filtration precision ranging from 1 to 200 microns, and can be tailored in thickness (13 mm), width (up to 2 meters), and surface treatments such as singed, calendared, or PTFE-coated finishes. These customizations allow adaptation to many applications, from fine dust collection to liquid filtration.Q: What is the typical process for installing and using Needle Punch Filter Felt in filtration systems?

A: Installation typically involves cutting the felt to fit the filter frames or housings, using rolls or sheets as needed. Edges can be supplied ultrasonic or heat welded for strength, or stitched if required. The product is suitable for both dry and wet filtration processes. Simply follow system guidelines for positioning and replacement to maximize operational efficiency.Q: When should the Needle Punch Filter Felt be replaced during operation?

A: Replacement intervals depend on application, dust loading, and process environment. Signs for replacement include reduced airflow, higher pressure drop, or visible clogging. Regular monitoring ensures that the filter performs efficiently and prolongs the operational life of associated equipment.Q: Where can this filter felt be effectively used?

A: It is ideal for dust collectors, industrial filtration units, liquid separation equipment, and specialized filtration systems in chemical, food, and manufacturing industries. Its robust build and compatibility with a range of chemicals (excluding strong acids and alkalis) make it suitable for demanding industrial settings.Q: What benefits does Needle Punch Filter Felt offer over traditional woven filters?

A: Nonwoven needle punch construction provides a smooth, uniform texture, high tensile strength, better abrasion resistance, and lower shrinkage. These qualities increase dust holding capacity and service life while allowing precise control over filtration parameters, supporting efficient and reliable filtration in various environments.Q: How should Needle Punch Filter Felt be stored to maintain its quality?

A: To preserve filter efficacy, store rolls or sheets in a cool, dry, and well-ventilated area, away from direct sunlight and corrosive chemicals. Proper storage prevents moisture absorption, deformation, or chemical damage before installation.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें