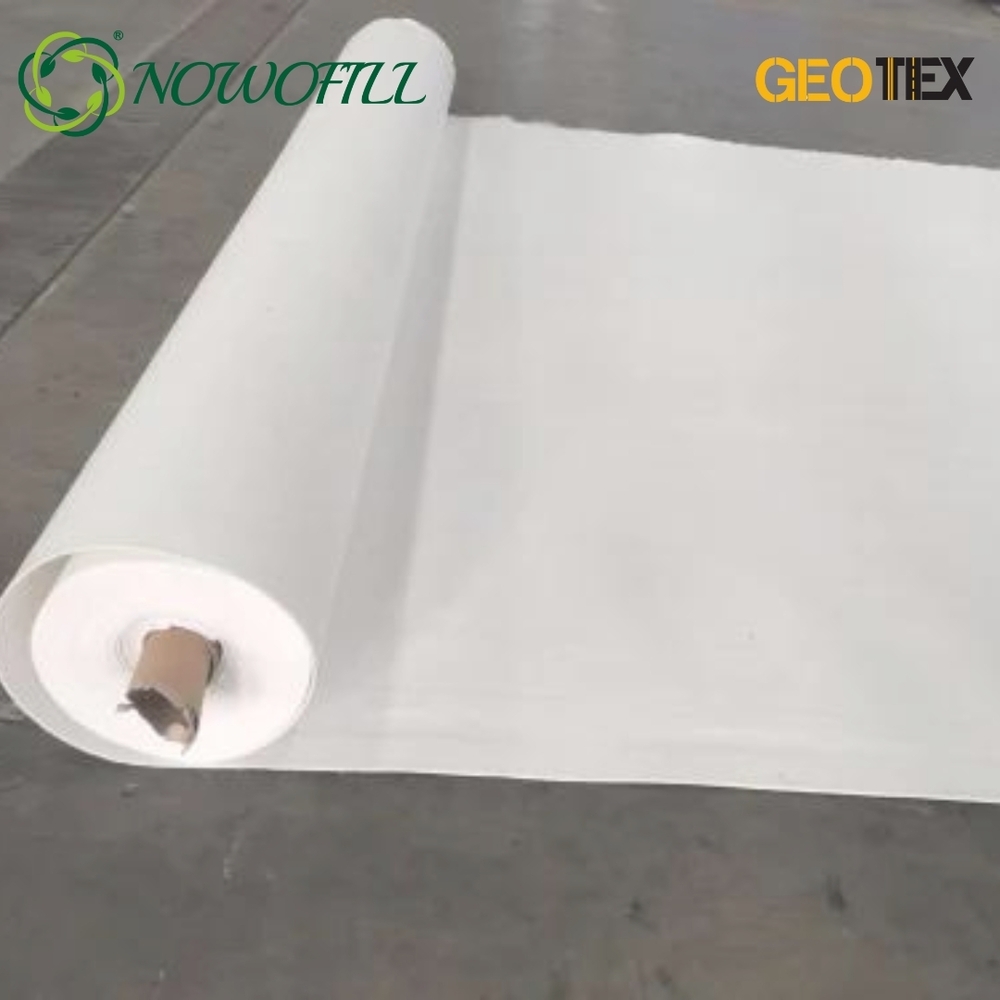

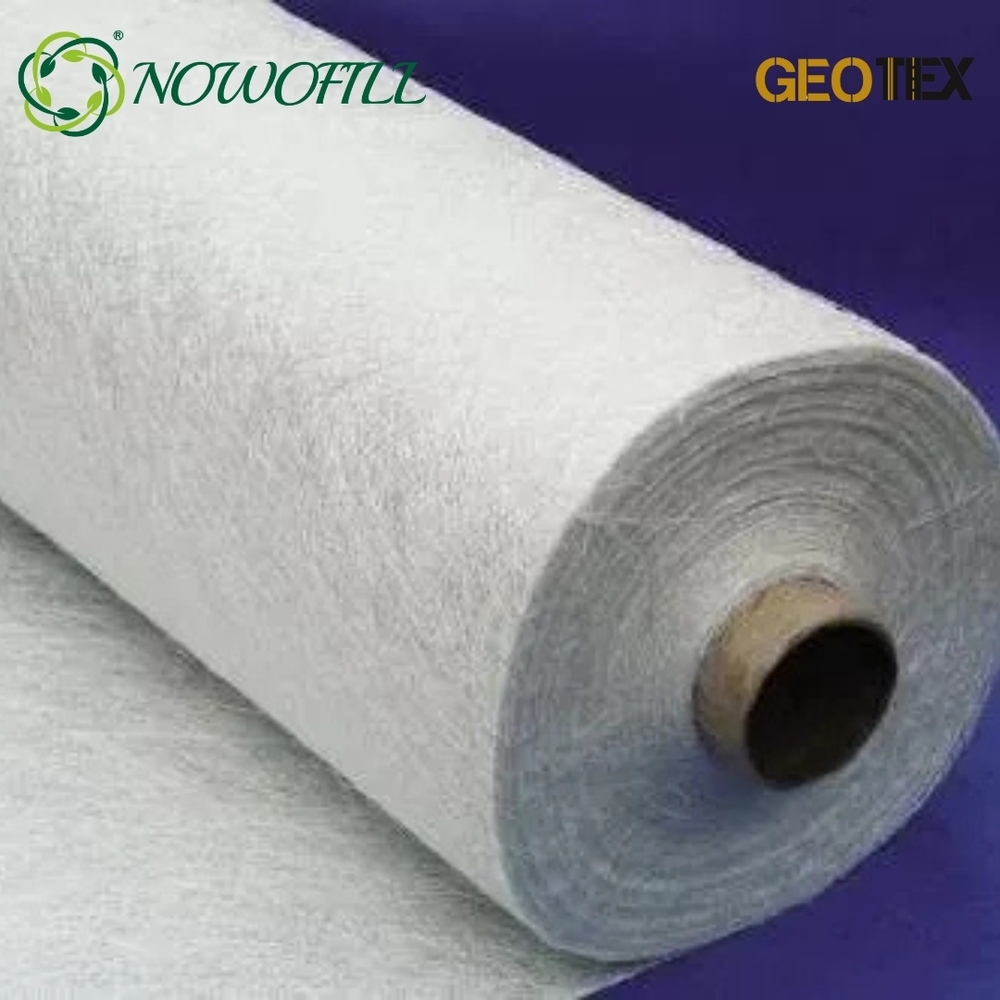

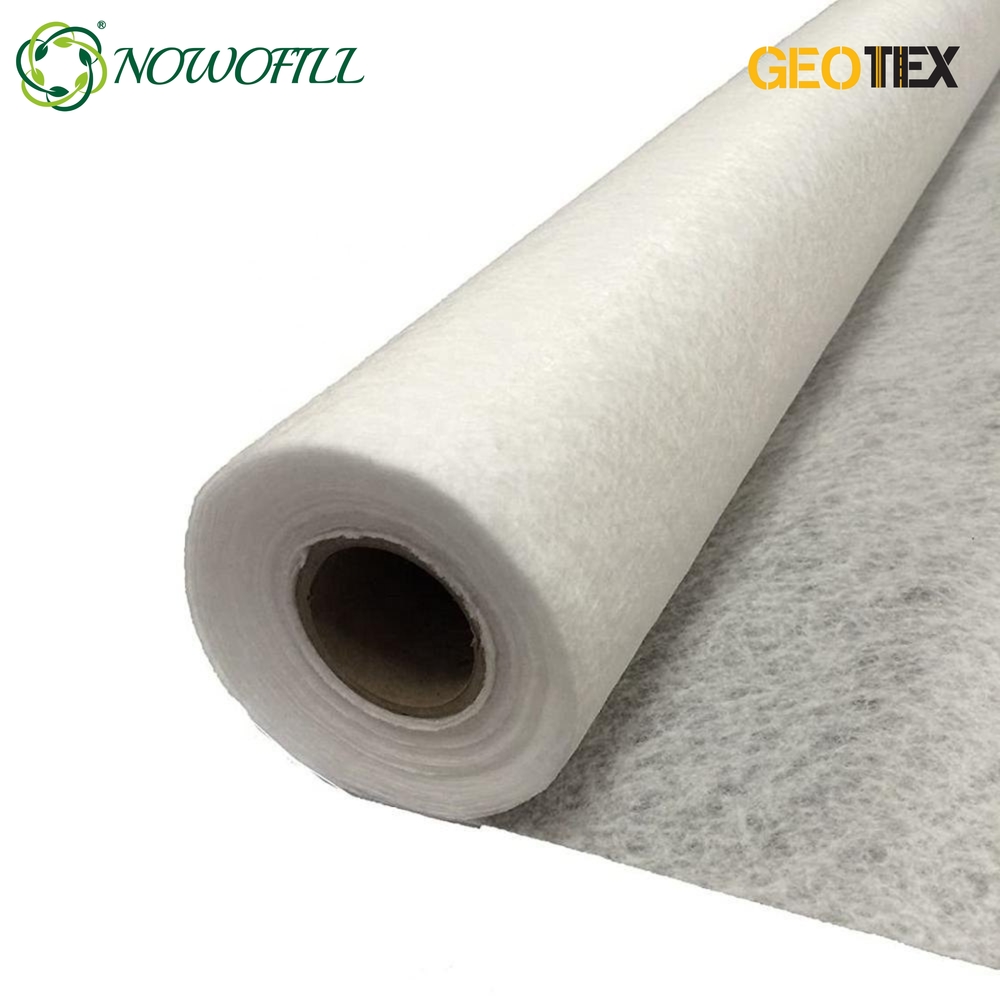

Geotextile Needle Punch - Non.

Price 26 INR/ Meter

Geotextile Needle Punch - Non. Specification

- Print Type

- Plain

- Usage & Applications

- Filling material

- GSM

- 200

- Material

- Polyester

- Color

- White

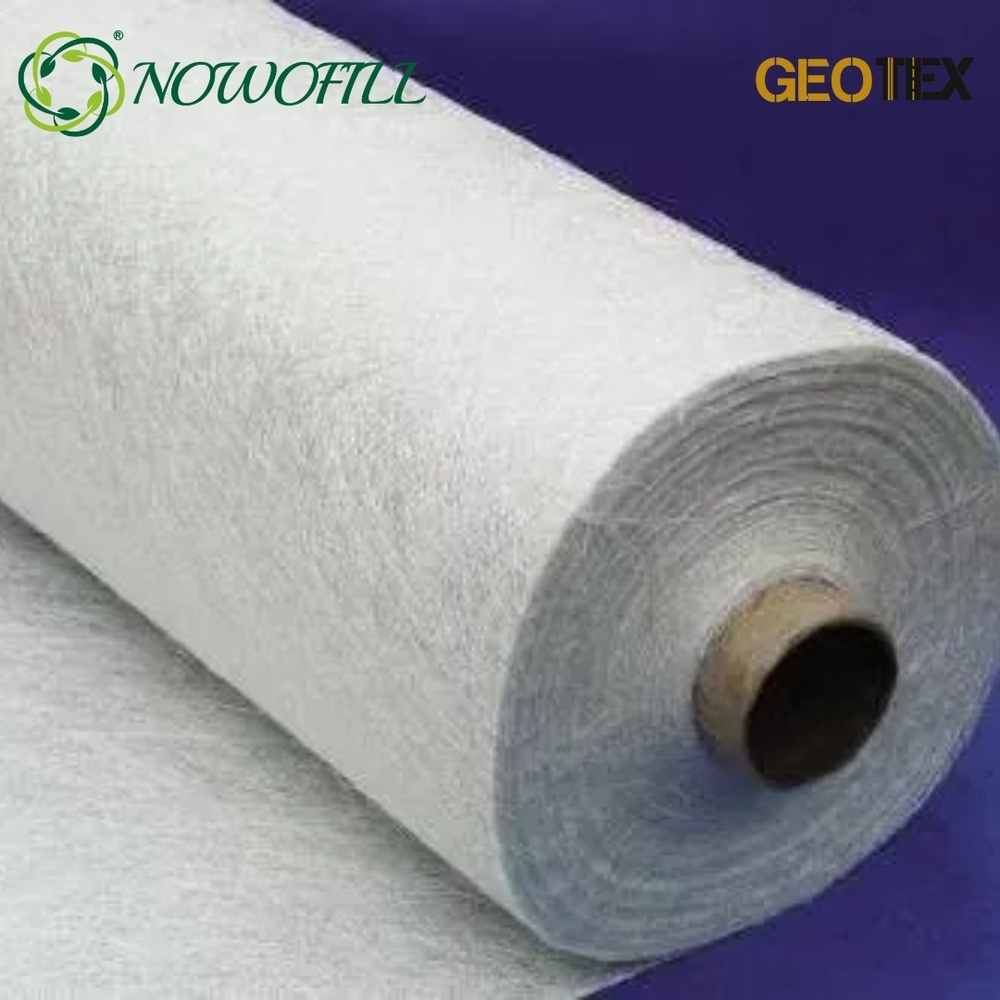

- Width

- 40-45 Inch (in)

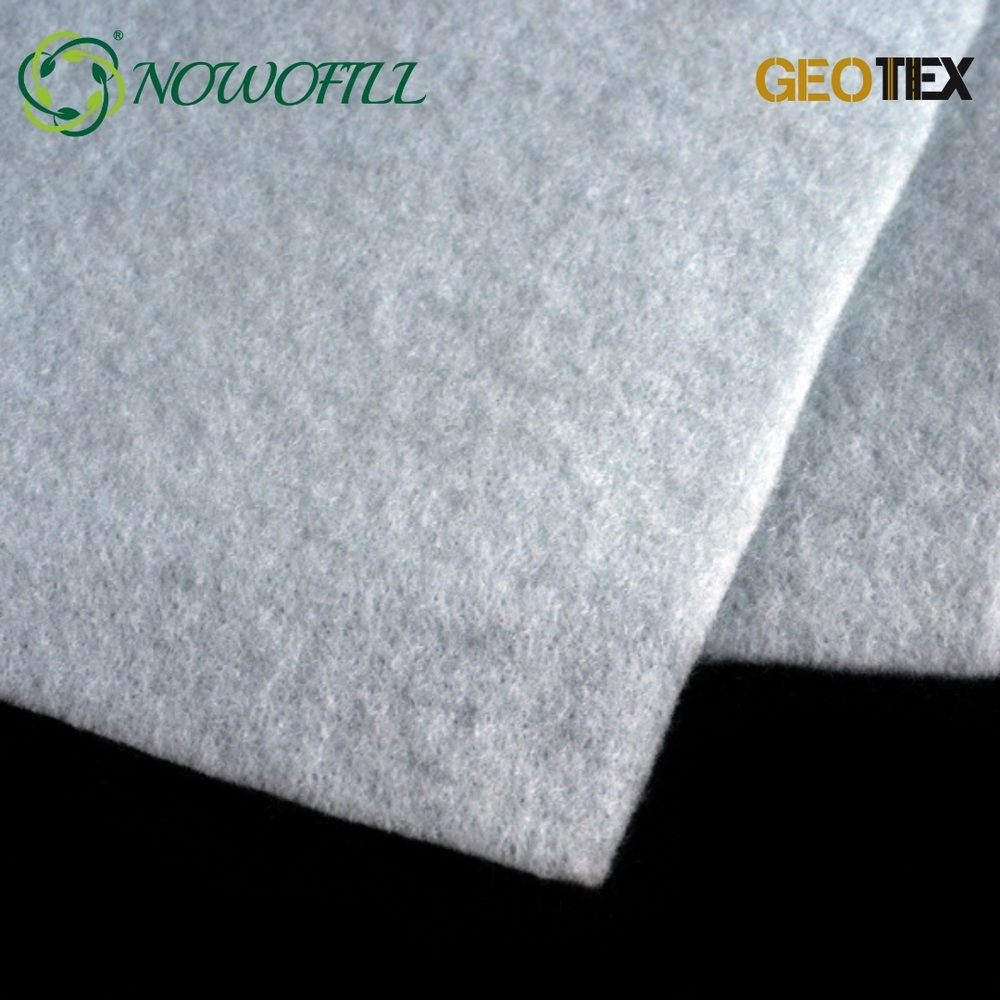

- Fabric Type

- Geotextile

- Application

- Landfill liners and capping systems

- Georgette Texture

- Plain

- Georgette Style

- Non Woven

- Characteristics

- Light in Weight, Environmental Friendly, Tear-Resistant

- Length x Width

- 1000 Meter (m)

Geotextile Needle Punch - Non. Trade Information

- Minimum Order Quantity

- 1000 Meter

- FOB Port

- LDPE Jute

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Geotextile Needle Punch - Non.

Nowofill is a high-strength, durable fabric manufactured using needle-punching technology from polypropylene or polyester fibers. It provides excellent soil stabilization, filtration, drainage, and reinforcement for civil and environmental engineering applications. Ideal for roads, railways, embankments, landfills, and erosion control, this geotextile ensures long-term structural stability, efficient water management, and enhanced durability in demanding construction projects.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Geotextile Products Category

Geotextile For Soil Erosion.

Price 25 INR / Meter

Minimum Order Quantity : 1000

Material : Polyester

Color : White

Fabric Type : Geotextile

Print Type : Plain

Geotextile Roof Garden Fabric .

Price 25 INR / Meter

Minimum Order Quantity : 1000

Material : Polyester

Color : White

Fabric Type : Geotextile

Print Type : Plain

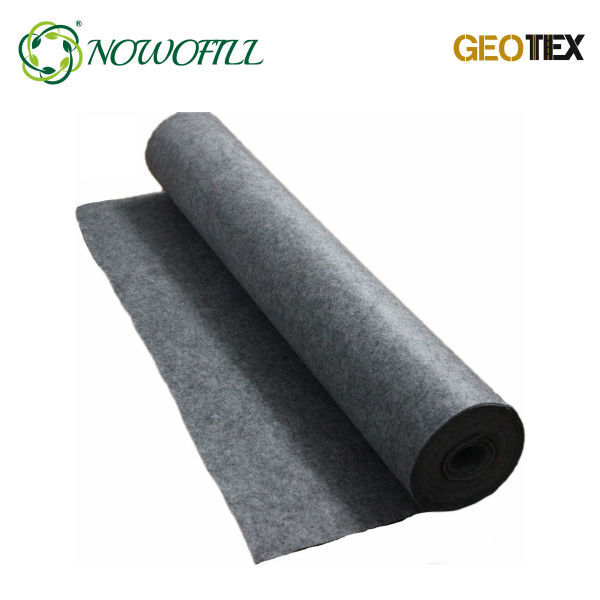

Non Woven Geotextile .

Price 22 INR / Square Meter

Minimum Order Quantity : 5000 Square Meters

Material : Polyester

Color : Grey

Fabric Type : Geotextile

Print Type : Plain

Civil Work Non Wovens Geotextiles.

Price 22 INR / Square Meter

Minimum Order Quantity : 5000 Square Meters

Material : Polyester

Color : Black

Fabric Type : Geotextile

Print Type : Plain

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free